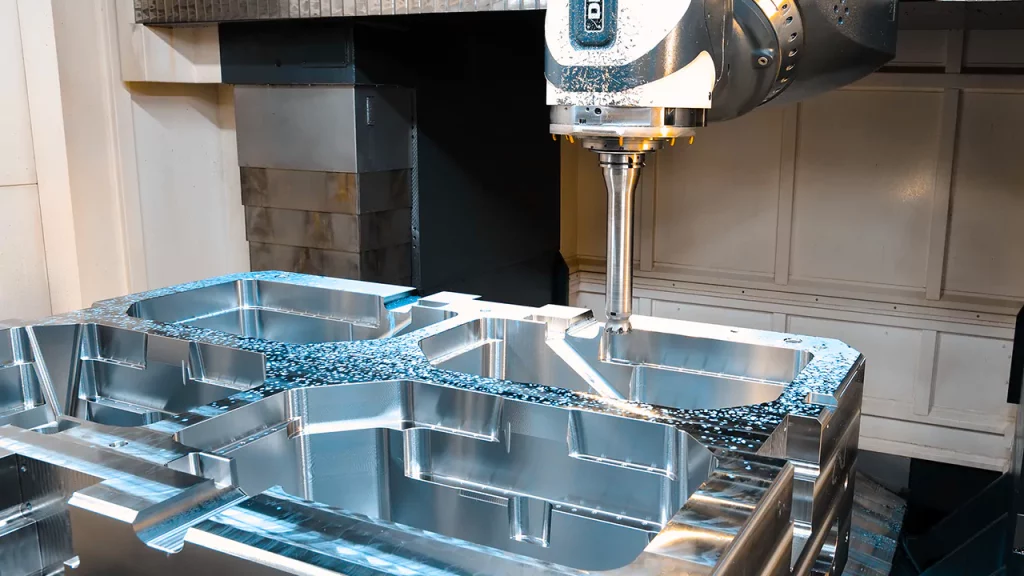

Tooling

For plastic, metal, and composite parts, JINOO advanced CNC machining equipment and products-paired with efficient mold design and manufacturing-supports a wide range of materials. We deliver precision machining services with micron-level accuracy, ensuring consistency and cost-effectiveness through strict process control to meet the highest quality standards.

JINOO 精诺

Application Scenario

JINOO’s Carbide Drill Bits: for precision drilling of high hardness materials, such as cooling holes of tool shanks, cooling waterways of moulds, mounting holes of gauges.

JINOO’s Cemented Carbide End Mills: for milling of complex shapes and high hardness materials, such as mould cavities, cutting edge shaping of tools, precision machining of mechanical parts.

JINOO’s Carbide Reamer: used for precision machining of high-precision holes, such as precision holes for toolholders and fixtures, positioning holes for precision components, measuring holes for gauges.

Advantages

High hardness and wear resistance: suitable for machining high hardness materials, prolonging tool life and reducing replacement frequency.

High temperature resistance and stability: maintain stable performance in high temperature and high speed cutting to meet the needs of high efficiency and high precision machining.

High precision and surface quality: achieve high precision machining, improve the surface quality of the workpiece, reduce the follow-up treatment.

Adaptation to complex processing needs: can efficiently process complex surfaces, applicable to a variety of processing methods.

Industry convenience

Efficient machining shortens cycle time, long-life tools reduce replacement costs.

Stable cutting performance ensures processing consistency and reduces defective rate.

Support high-speed, automated processing, to meet the needs of new material processing.

Support dry cutting, reduce pollution and improve material utilisation.