STRONGER

DRILLING TOOLS

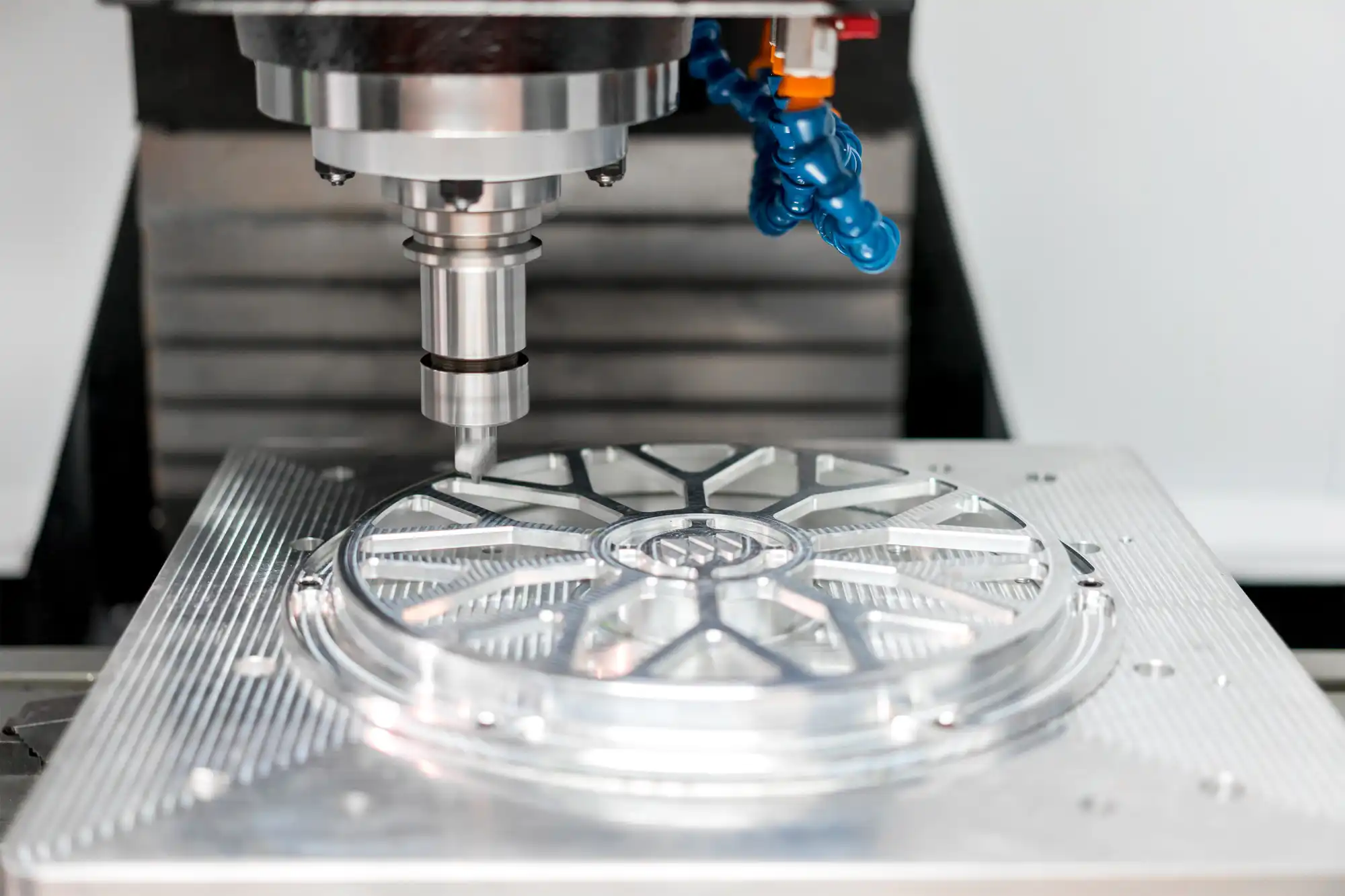

JINOO provides industry-leading drilling tools solutions worldwide, providing superior performance to various industries with innovative technology and machinery, and also rigorous quality control.

“JINOO was founded in 2006, with over 18 years of professional experience manufacturing the Carbide Drill Bits & End Mills and Reamers. The company has passed the ISO 9001 quality management system. We have two individual manufacturing bases for a total excess of 25000 square meters and an excess of 30 production technicians; we imported “WALTER Power, Micro and Vision” from Germany, “ANCA MX5” from Australia, “Rollomatic NP5” from Switzerland, Group of Senior technical engineer for more than 40 years experiences for the R&D department.”

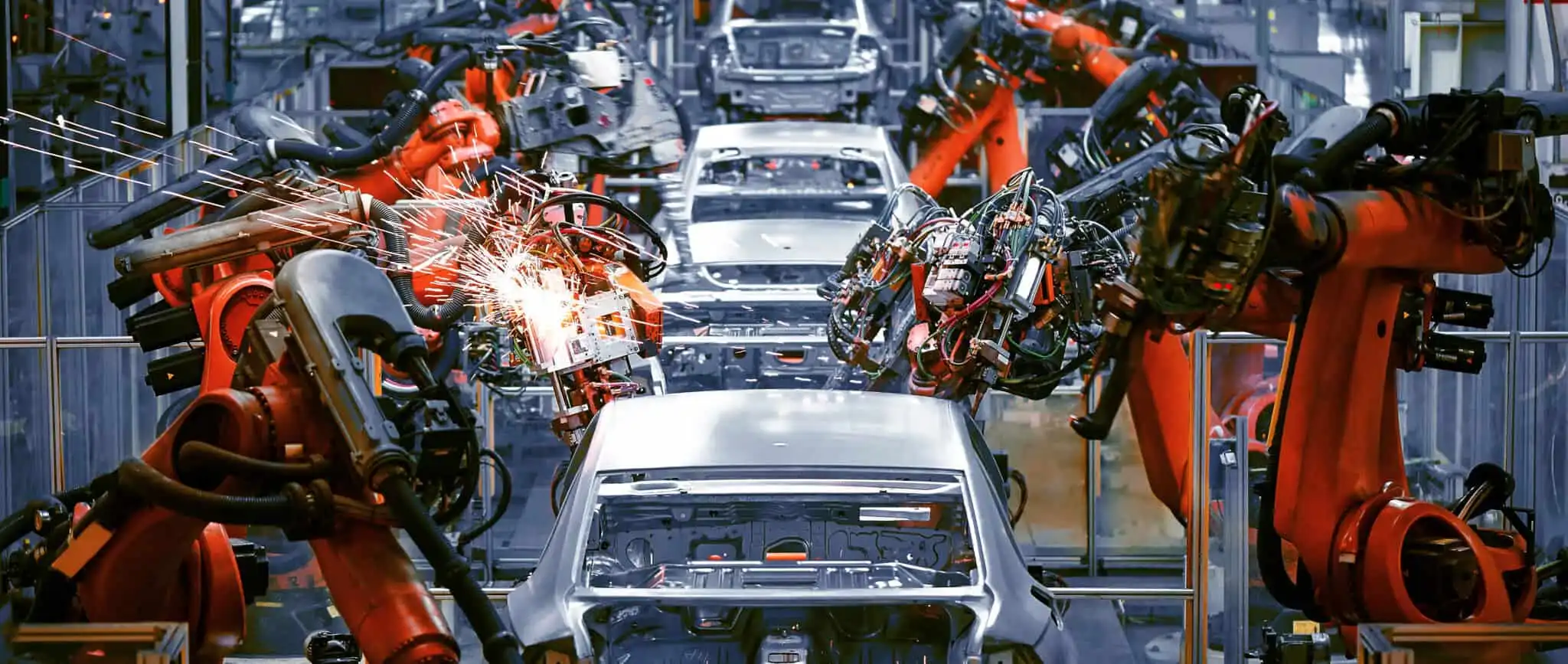

JINOO Tools offers fast, reliable and on-time delivery; and 24/7 support across North America, Europe, the Middle East, and Asia. We provide flexible, tailored solutions for both small and large orders.

JINOO's Drilling Tools - Where Accuracy Meets Durability

JINOO's Drill Bits was one of the most cost-effective drilling tools in the world, most Fortune 500 clients satisfied with our Carbide Drill Bits. Built with technology and quality for flawless performance.

Explore Our Product Range

- Versatile Material Compatibility: Suitable for machining steel, cast iron, stainless steel, and non-ferrous metals.

- Enhanced Edge Design: Curved edge with a rounded back face for improved durability and cutting performance.

- Optimized for Productivity: Features optimized edge chamfering, enabling higher feed speeds and enhanced productivity.

- Advanced Coating and Precision: High-quality tungsten steel with a new versatile substrate coating, processed using high-precision CNC machines for strong centering ability, stable dimensional accuracy, and excellent surface quality—ideal for systems with high rigidity.

- Ideal for Steel and Cast Iron: Suitable for materials with hardness ranging from HRC25 to HRC48.

- Enhanced Edge Strength: Features unique linear chip edge treatment technology, improving edge strength and anti-chipping performance.

- AITIN Coating for Durability: Equipped with a new AITIN coating that offers excellent wear resistance.

- Advanced Substrate and Precision Engineering: High-quality tungsten steel with a versatile new substrate coating, processed by high-precision imported CNC machines. Provides strong centering ability, stable dimensional accuracy, and a superior surface finish, especially in high-rigidity systems.

- Efficient Drilling: Ideal for high-efficiency drilling of steel, cast iron, and stainless steel.

- Balanced Toughness and Wear Resistance: New base material provides an optimal balance between toughness and wear resistance.

- Advanced Nano-Coating: Features AITIN base nano-coating with unique post-coating treatment for enhanced durability.

- Optimized Design: Improved groove and drill tip design offer excellent self-centering, chipbreaking, and chip evacuation performance.

- High Precision and Versatility: Made from high-quality tungsten steel with a new versatile substrate coating, processed with high-precision CNC machines, ensuring stable dimensional accuracy and superior surface quality, particularly in high-rigidity systems.

- Versatile Material Compatibility: Suitable for machining steel parts, cast iron, stainless steel, and non-ferrous metals.

- Enhanced Edge Design: Features a curved edge and rounded back face for better durability.

- Optimized Chamfering and Productivity: High feed speed and productivity due to optimized edge chamfering.

- Advanced Coating and Substrate: New substrate coating enhances versatility and tool life.

- Precision Engineering: Made from high-quality tungsten steel, processed with high-precision imported CNC machines.

- Superior Centering Ability: Ensures stable dimensional accuracy and excellent surface finish, ideal for systems with high rigidity.

- Versatile Material Compatibility: Suitable for machining steel parts, cast iron, stainless steel, and non-ferrous metals.

- Enhanced Edge Design: Features a curved edge and rounded back face for better durability.

- Optimized Chamfering and Productivity: High feed speed and productivity due to optimized edge chamfering.

- Advanced Coating and Substrate: New substrate coating enhances versatility and tool life.

- Precision Engineering: Made from high-quality tungsten steel, processed with high-precision imported CNC machines.

- Superior Centering Ability: Ensures stable dimensional accuracy and excellent surface finish, ideal for systems with high rigidity.

- Versatile Material Compatibility: Suitable for machining steel parts, cast iron, stainless steel, and non-ferrous metals.

- Enhanced Edge Design: Features a curved edge and rounded back face for better durability.

- Optimized Chamfering and Productivity: High feed speed and productivity due to optimized edge chamfering.

- Advanced Coating and Substrate: New substrate coating enhances versatility and tool life.

- Precision Engineering: Made from high-quality tungsten steel, processed with high-precision imported CNC machines.

- Superior Centering Ability: Ensures stable dimensional accuracy and excellent surface finish, ideal for systems with high rigidity.

JINOO's news & Article

Keep in track with JINOO’s Latest Products, News and Industry Insights!

2024-2031 Trends and Future Outlook for the DTH Drilling Tools Market

Market Overview The global Down-the-Hole (DTH) drilling tools market was valued at $3.5 billion in 2022 and is projected to

Carbide Tipped Masonry Drill Bits Market by Application: Global Trends and Future Projections 2023-2054

Carbide Tipped Masonry Drill Bits Market By Application | Overview The global Carbide Tipped Masonry Drill Bits market is experiencing

Explore our solutions

Discover how our decades of expertise in tool engineering can help your business to raise the market competitiveness, in both precise quality and premium quality-price ratio with high-efficiency solutions, delivering faster and more durable cutting tools than ever before.

WE ARE GLOBAL PARTNERS

Equip your product with the top tools and expertise. Our precision-engineered drill bits and global support ensure success in every industry. Contact us today to collaborate with a trusted global partner to succeed together.

DRILLING TOOLS EXPERTS

Learn how our professional tooling solutions can make your drilling faster and more efficient. Let us help you optimize your next products.