| Model number | Blade diameter d1 (m7) | Thread Size M Metric | Shank diameter d2(h6) | Overall length l1 | Groove length l2 | Maximum depth of cut l3 | Shank length l4 | Quantity | Cart |

|---|---|---|---|---|---|---|---|---|---|

| X1540-0100 | 1 | 3 | 4cm | 50 | 0 | 0 | 0 | 0 | |

| X1540-0150 | 1.5 | 4 | 4cm | 50 | 0 | 0 | |||

| X1540-0200 | 2 | 6 | 4cm | 50 | 0 | 0 | |||

| X1540-0250 | 2.5 | 8 | 4cm | 50 | 0 | 0 | |||

| X1540-0300 | 3 | 8 | 4cm | 50 | 0 | 0 | |||

| X1540-0350 | 3.5 | 10 | 4cm | 50 | 0 | 0 | |||

| X1540-0400 | 4 | 12 | 4cm | 50 | 0 | 0 | |||

| X1540-0500 | 5 | 15 | 6cm | 50 | 0 | 0 | |||

| X1540-0600 | 6 | 16 | 6cm | 50 | 0 | 0 | |||

| X1540-0700 | 7 | 20 | 8cm | 60 | 0 | 0 | |||

| X1540-0800 | 8 | 20 | 8cm | 60 | 0 | 0 | |||

| X1540-1000 | 10 | 25 | 10cm | 75 | 0 | 0 | |||

| X1540-1200 | 12 | 30 | 12cm | 75 | 0 | 0 | |||

| X1540-1400 | 14 | 40 | 14cm | 80 | 0 | 0 | |||

| X1540-1600 | 16 | 45 | 16cm | 100 | 0 | 0 | |||

| X1540-1800 | 18 | 45 | 18cm | 100 | 0 | 0 | |||

| X1540-2000 | 20 | 50 | 20cm | 100 | 0 | 0 |

| Size Range | D(m7) | d(h6) |

| ≥2-3 | +0.002/+0.012 | 0.000/-0.006 |

| >3-6 | +0.004/+0.016 | 0.000/-0.008 |

| >6-10 | +0.006/+0.021 | 0.000/-0.009 |

| >10-18 | +0.007/+0.025 | 0.000/-0.011 |

| >18-20 | +0.008/+0.029 | 0.000/-0.013 |

Unit(mm)

Our products through the most advanced manufacturing process and strict quality management system to ensure the accuracy and reliability of each product.

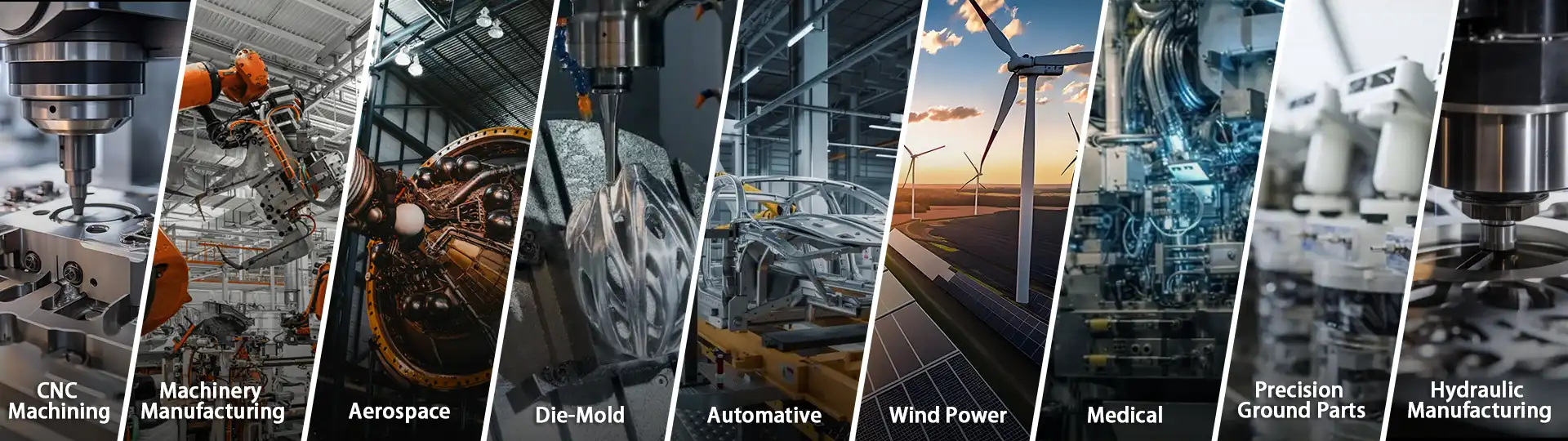

Our products and services are available throughout North America, the EU, the Middle East, and Asia, and are trusted by companies such as Apple, Samsung, Boeing, Airbus, and more.

Our team of senior technical engineers with more than 40 years of experience is dedicated to product development and testing to meet the changing needs of our customers.

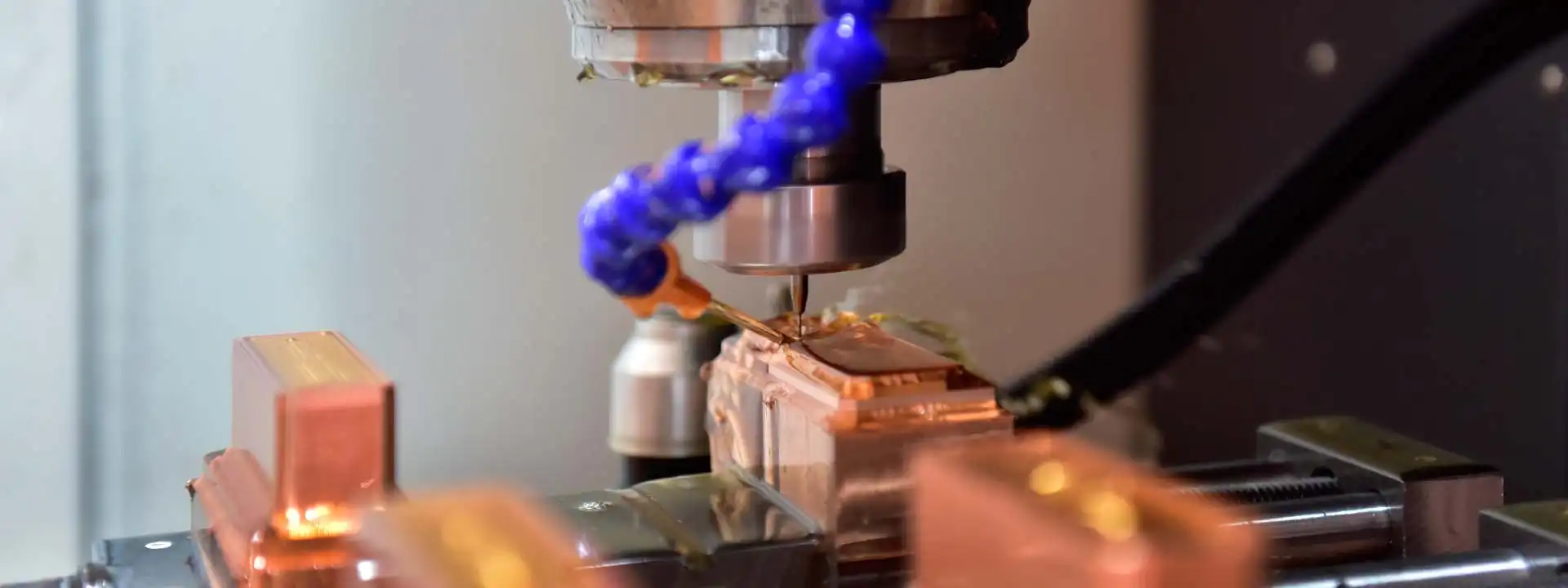

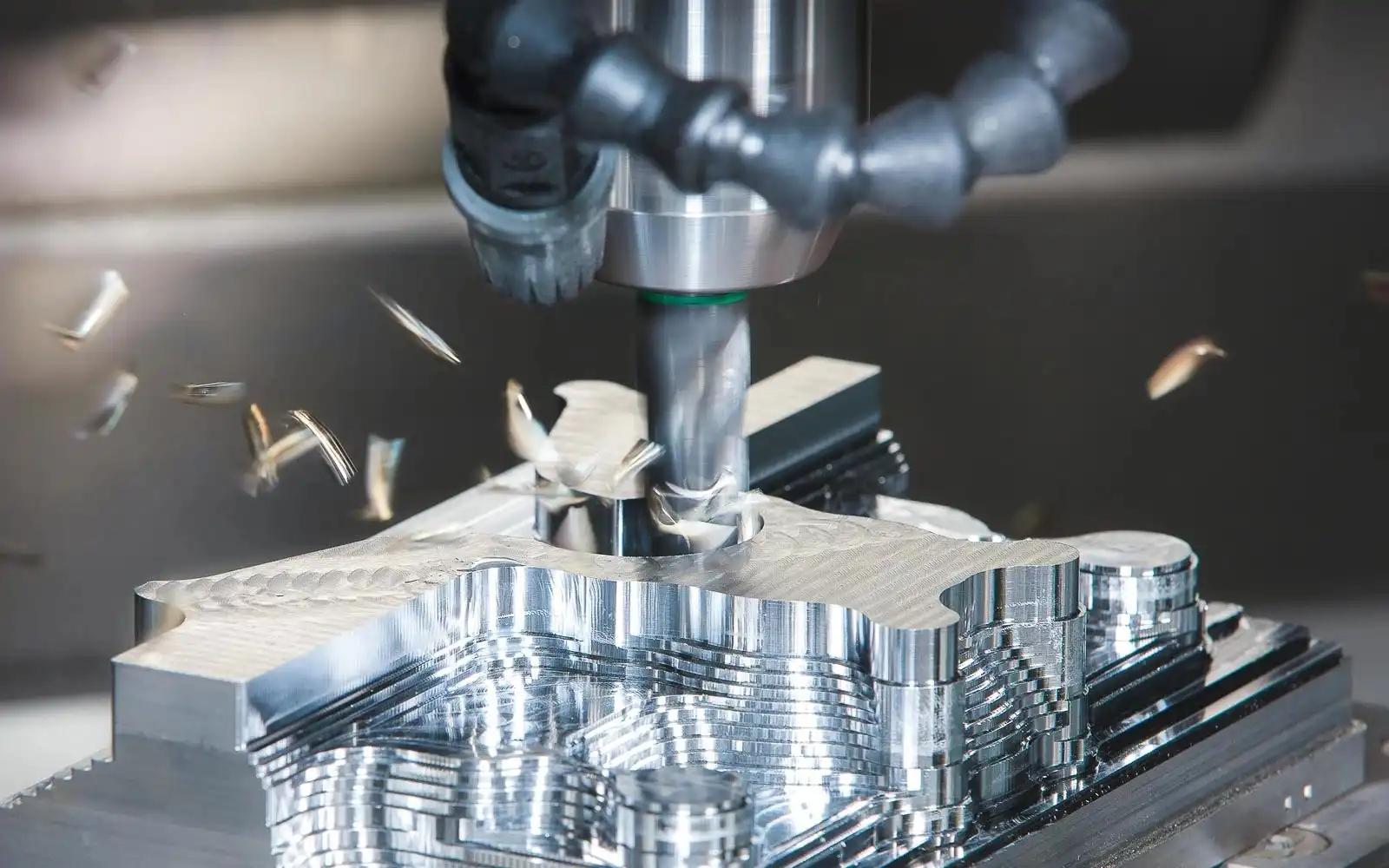

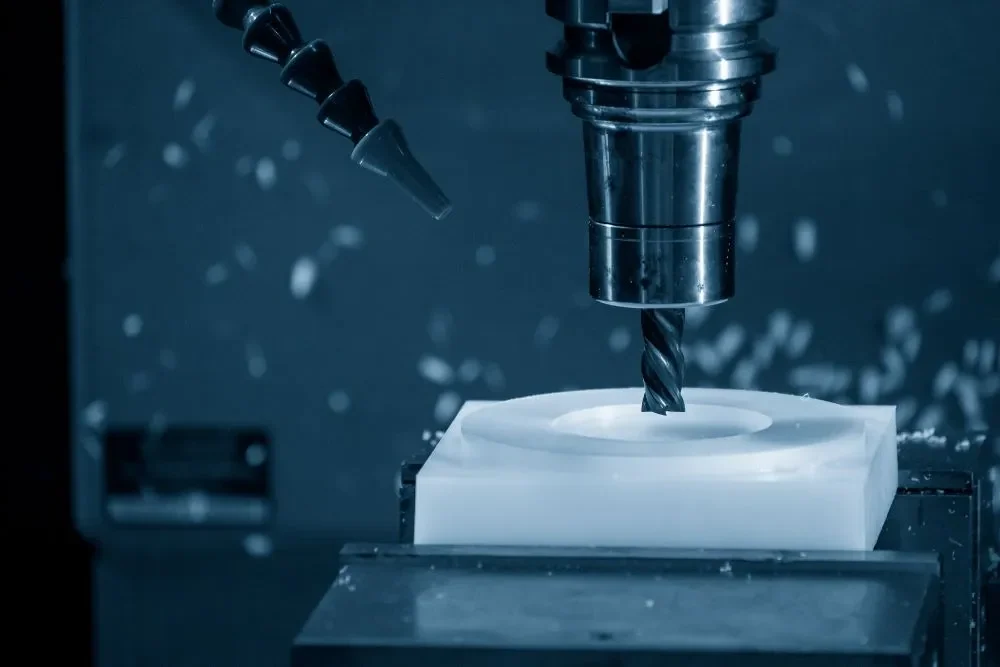

Milling is one of the most varied production processes in metalworking. The process creates precise, complex components that are used in many areas. JINOO provides suitable milling tools for machining different materials depending on the application. The range extends from all-rounders to specialist tools, from conventional roughing cutters to modern HPC/HSC strategies such as dynamic trochoidal milling (GTC) or iMachining (SolidCAM). Different cutting materials are also used for the milling cutters.

Threading Tools, for the production of threads have a critical task in common: They are applied at the end of the production chain, when component parts or individual parts are practically finished. JINOO threading tools operate with process reliability – perfect for a demanding machining task at the end of the production chain.

There are several processes to lead to the desired result. No matter if the user decides on fluteless taps, thread taps or thread milling cutters, together with our product management and experienced application technicians we work out the most economical solution for producing a thread.

With the HR 500 high-performance reamers, you will find the ideal tool solution for all diameters from 1.97 to 150 mm. To always be able to apply the optimal HR 500 high-performance reamer there is a choice of various HR 500 types.

| Dimensions | N/A |

|---|---|

| 产品系列 | X1540-0100, X1540-0150, X1540-0200, X1540-0250, X1540-0300, X1540-0350, X1540-0400, X1540-0500, X1540-0600, X1540-0700, X1540-0800, X1540-1000, X1540-1200, X1540-1400, X1540-1600, X1540-1800, X1540-2000 |

Follow us to get the latest news from JINOO!

* By subscribing you agree to with our Privacy Policy and provide consent to receive updates from our company.

Founded in 2006, Changzhou Jingnuo Tool specializes in solid carbide drilling tools, including carbide drill bits, milling cutters, reamers, and custom drill bits. Our products are sold globally, with a 25000+ square meter workshop.

| P | Steel, high-alloyed steel / Ferritic stainless steel, Martensitic stainless steel |

|---|---|

| M | Stainless steel |

| K | Grey cast iron, spher, graphite/mall. cast iron |

| N | Aluminium and other non-ferrous metals |

| S | Special, super and titanium alloys |

| H | Hardened steel and chilled cast iron |

On the following programme pages you will find for every tool recommendations regarding suitability for the application groups and details of max. tensile strength and harness: