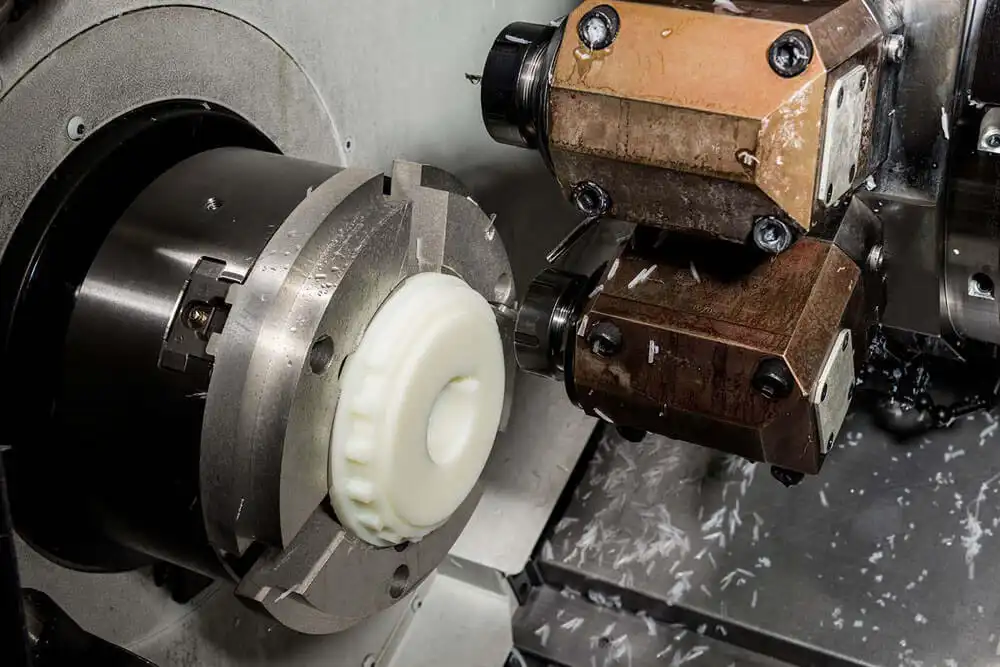

Plastic

“In the plastic industry, JINOO tools are indispensable for producing precise and complex parts. They enable the efficient machining of plastic materials, allowing for intricate designs and tight tolerances. By utilizing JINOO’s CNC technology, manufacturers achieve high-quality, consistent results while reducing production time and costs.”

JINOO 精诺

Chief Executive Officer

Application Scenario

JINOO’s Carbide Drill Bits: for high precision drilling of plastic moulds and products, reducing delamination and burrs.

JINOO’s Cemented Carbide End Mills: efficient processing of mould cavities, trimming and milling of composite materials to improve product quality.

JINOO’s Carbide Reamer: precision reaming of mould guide holes and plastic parts assembly holes to ensure assembly accuracy.

Advantages

High precision and surface quality:

1.Achieve high precision machining and meet the dimensional requirements.

2.Improve surface finish, reduce burrs, and reduce the cost of subsequent processing.

High wear resistance and long life:

1.Extend tool life and reduce replacement frequency.

2.Adapt to plastics containing fillers and maintain machining stability.

Improved machining efficiency:

1.Withstand high cutting speeds and reduce machining time.

2.Reduces downtime and ensures production continuity.

Adaptation to diverse materials:

1.Suitable for processing a wide range of plastics and composite materials.

Reduce processing difficulty and improve processing quality.

Industry convenience

Stable tool performance to ensure product quality consistency, reduce the rate of defective products.

Save tool and material costs, reduce scrap and rework.

Meet the needs of high-volume production and support automated and intelligent production lines.

Reduce waste generation, support dry processing, reduce environmental pollution.