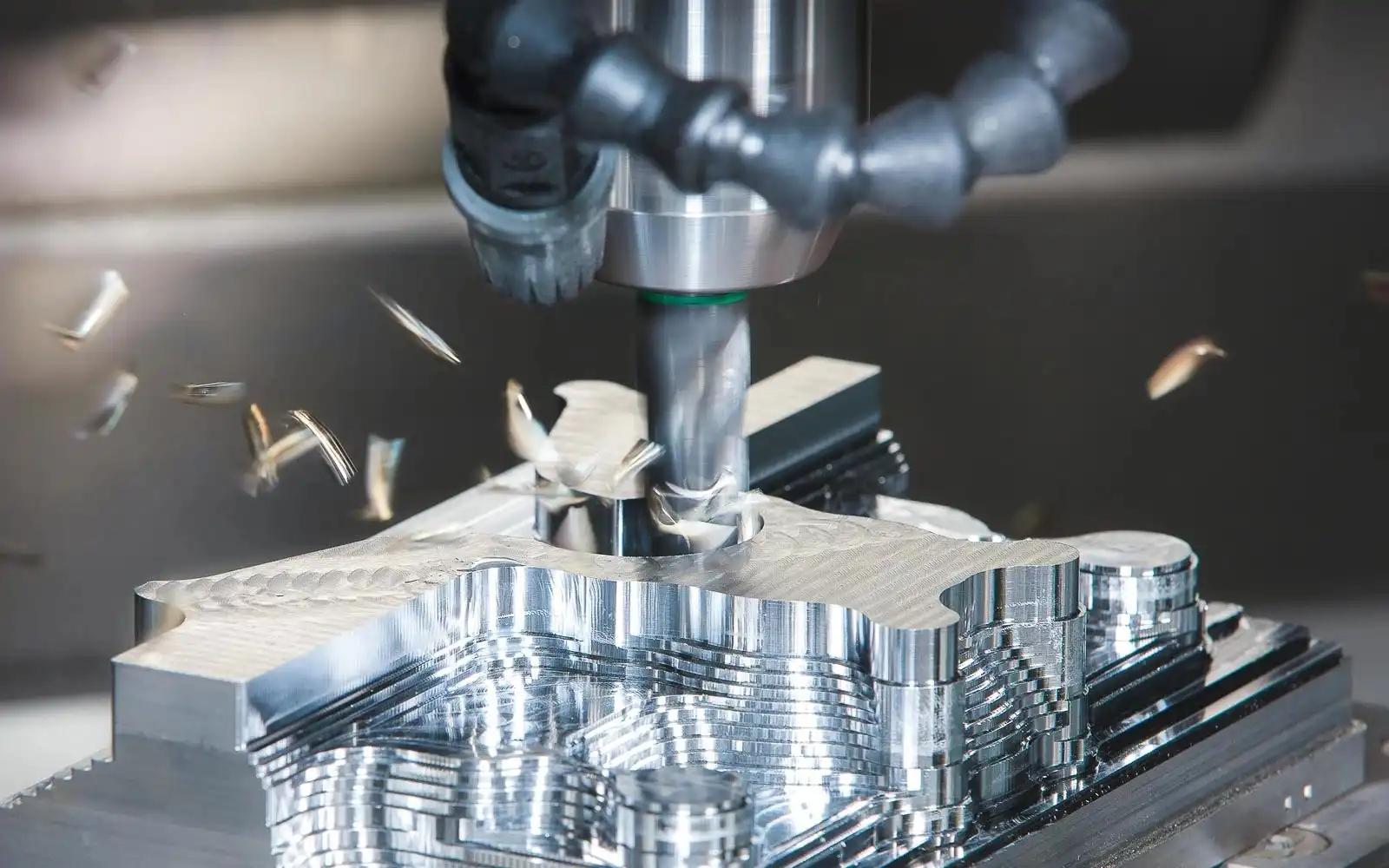

CNC Mechining

“Our CNC machining equipment supports various materials, including metals, plastics, and composites, delivering precision machining services with micron-level accuracy to meet the highest quality standards.”

JINOO 精诺

Application Scenario

JINOO’s Carbide Drill Bits: used for drilling holes in carbon steel, stainless steel, titanium alloy and other materials, widely used in aerospace, automotive manufacturing, and precision hole machining in mould processing.

JINOO’s Cemented Carbide End Mills: suitable for plane, groove, contour and complex surface machining, commonly used in mould cavities, mechanical parts and automotive transmission system for efficient cutting.

JINOO’s Carbide Reamers: used for hole dressing and surface quality improvement in hydraulic systems, precision machinery and aircraft engines.

Advantages

High hardness and wear resistance: suitable for machining high hardness materials, extending tool life and reducing replacement frequency.

High-temperature resistance and high-speed cutting: withstand high-temperature cutting, suitable for high-volume high-speed production.

High precision and surface quality: suitable for strict precision and surface requirements, improving workpiece quality.

Wide material adaptability: efficient cutting of aluminium, stainless steel, titanium alloy and many other materials.

Industry convenience

Reduce tool replacement, shorten machining time and reduce production costs.

Ensure machining accuracy, reduce defective rate, suitable for high-demand industries.

Good stability, adapt to unmanned, intelligent processing needs.