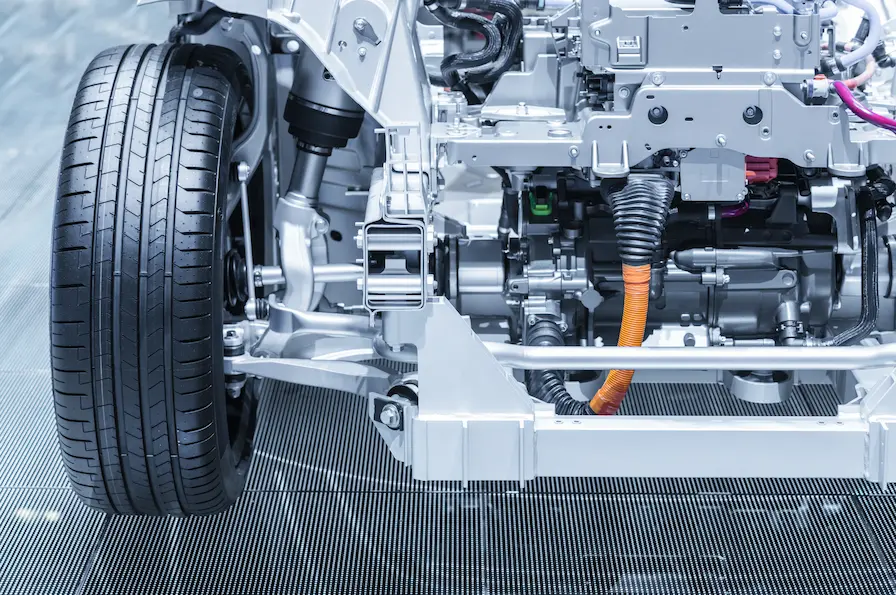

Automative

In the automotive industry, JINOO CNC tools are used to precisely machine metal and plastic parts such as engine components, transmission gears, and custom body panels. They enable high-precision manufacturing, ensuring consistency and efficiency in producing complex parts while meeting strict quality and safety standards.

JINOO 精诺

Appication Scenario

JINOO’s Carbide Drill Bits: Used for drilling holes in alloy steel, stainless steel, aluminium alloy and other materials. Typical applications include oil holes and bolt holes in engine parts (such as cylinder blocks and cylinder heads), connection holes in chassis and suspension systems, and hole machining in transmission systems, which require high precision and reliability.

JINOO’s Cemented Carbide End Mills: Used for milling of various parts, including flat, bevelled and complex contours of engine components, machining of cavities and cores in mould making, as well as shapes and mounting parts of body parts, meeting the requirements of high precision and high surface quality.

JINOO’s Carbide Reamers: for high-precision finish machining of holes, such as precision holes in engine and gearbox housings, valve body and pipe connection holes in hydraulic system components, and injector seat holes in fuel system components, ensuring assembly accuracy and performance stability.

Advantages

High hardness and wear resistance: Suitable for machining high-strength materials, prolonging tool life, reducing replacement frequency and improving productivity.

High-temperature resistance and stability: maintain stable performance in high-speed and high-temperature machining to ensure the consistency of machining quality.

High precision and high quality surface: achieve micron-level machining precision, improve the fatigue strength and service life of parts.

Adapt to complex machining needs: capable of efficiently machining complex contours and a variety of materials to meet the requirements of difficult machining.

Industry convenience

Allow higher cutting speeds and feeds, shorten machining cycles and reduce tool costs.

Stable cutting performance ensures consistency in mass production and meets strict quality standards.

Suitable for high-speed machining centres and automated production lines to meet the demands of mass production.

Suitable for dry or micro-lubricated cutting, reducing environmental pollution and improving material utilisation.